Cleaning a Warehouse: The Ultimate Guide

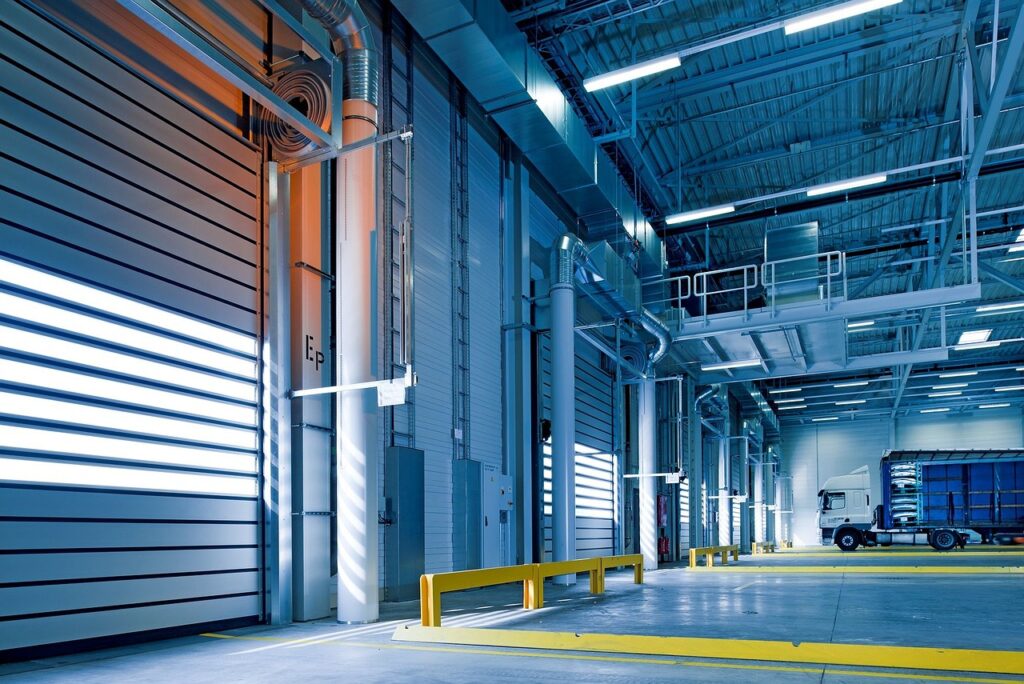

When it comes to cleaning a warehouse, meticulous planning and preparation are essential for ensuring a safe and efficient working environment.

In this comprehensive guide, we’ll explore the crucial steps involved in preparing and planning for the cleaning of a warehouse.

Table of Contents

Preparation and Planning: Cleaning a Warehouse

Introduction to Warehouse Cleaning

- Cleaning a warehouse is not just about maintaining appearances; it’s a critical aspect of ensuring a safe and productive working environment.

- Proper cleaning helps prevent accidents, minimizing the risk of injuries, and safeguarding inventory and equipment.

Importance of Maintaining Cleanliness in Warehouses

- Safety: A clean warehouse reduces the risk of slips, trips, and falls, which are among the most common workplace accidents.

- Productivity: A clutter-free and organized warehouse layout facilitates smooth operations, enhances workflow efficiency, and reduces the time spent searching for items.

- Regulatory Compliance: Many regulatory agencies, such as OSHA, have strict guidelines regarding cleanliness and safety in industrial settings.

Occupational Safety and Health Administration (OSHA) – Warehouse Safety

Understanding the Scope of Warehouse Cleaning

- Warehouse cleaning encompasses a wide range of tasks, including but not limited to:

- Sweeping and mopping floors

- Dusting shelves and racks

- Removing debris and obstructions from aisles

- Cleaning restrooms and break areas

- Disinfecting high-touch surfaces and equipment

Material Handling Institute (MHI) – Warehouse Cleaning Best Practices

Safety Precautions and Equipment Needed for Warehouse Cleaning

- Personal Protective Equipment (PPE): Proper PPE, such as gloves, safety goggles, and respiratory masks, should be provided to all cleaning staff to protect them from potential hazards.

- Cleaning Solutions: Depending on the nature of the surfaces and contaminants, various cleaning solutions like disinfectants, degreasers, and industrial-strength cleaners may be required.

- Equipment: Utilizing appropriate equipment, such as industrial floor scrubbers, sweepers, and high-pressure washers, can significantly improve the efficiency and effectiveness of warehouse cleaning operations.

- Training: Proper training should be provided to cleaning personnel to ensure they are proficient in handling equipment safely and using cleaning products correctly.

National Fire Protection Association (NFPA) – Fire Safety in Warehouses

Effective preparation and planning are the cornerstones of successful warehouse cleaning initiatives.

By understanding the importance of cleanliness, identifying the scope of tasks involved, and implementing proper safety measures and equipment, warehouse managers can create a safer, more productive work environment for their employees.

In the next part of this guide, we’ll delve deeper into the techniques and strategies for executing efficient warehouse cleaning operations.

Techniques and Strategies: Warehouse Cleaning

After laying the groundwork in the preparation and planning phase, it’s time to delve into the techniques and strategies for executing effective warehouse cleaning.

In this section, we’ll explore various methods, tools, and schedules to ensure your warehouse remains clean and organized.

Overview of Cleaning Methods for Warehouses

- Warehouse cleaning involves a combination of methods tailored to the specific needs of the facility. Some common cleaning methods include:

- Sweeping and Vacuuming: Effective for removing loose debris and dust from floors and hard-to-reach areas.

- Mopping and Scrubbing: Ideal for removing stubborn stains and spills from warehouse floors.

- Pressure Washing: Suitable for cleaning large surface areas and removing tough grime and contaminants.

Occupational Safety and Health Administration (OSHA) – Warehouse Safety

Step-by-Step Guide to Cleaning a Warehouse

- To ensure thorough and systematic cleaning, follow these steps:

- Preparation: Clear the workspace of any obstacles and ensure proper ventilation.

- Sweeping and Vacuuming: Start by removing loose debris and dust from the floors.

- Spot Cleaning: Address any spills or stains promptly to prevent them from spreading.

- Mopping and Scrubbing: Use appropriate cleaning solutions and equipment to thoroughly clean the floors.

- High-Level Cleaning: Don’t forget to clean high shelves, racks, and ceiling areas to eliminate dust buildup.

- Restroom and Break Area Cleaning: Ensure these areas are cleaned and sanitized regularly to maintain hygiene standards.

Material Handling Institute (MHI) – Warehouse Cleaning Best Practices

Choosing the Right Cleaning Products and Tools

- Selecting the appropriate cleaning products and tools is crucial for achieving optimal results:

- Cleaning Solutions: Choose products that are suitable for the surfaces being cleaned and environmentally friendly whenever possible.

- Equipment: Invest in high-quality cleaning equipment such as industrial scrubbers, sweepers, and pressure washers to streamline the cleaning process and improve efficiency.

National Fire Protection Association (NFPA) – Fire Safety in Warehouses

Implementing Regular Maintenance and Cleaning Schedules

- Establishing a regular maintenance and cleaning schedule is essential for keeping your warehouse clean and organized:

- Daily Cleaning Tasks: Assign daily tasks such as sweeping, spot cleaning, and maintaining cleanliness in high-traffic areas.

- Weekly Maintenance: Schedule deeper cleaning tasks like mopping, scrubbing, and equipment maintenance on a weekly basis.

- Monthly Inspections: Conduct monthly inspections to identify any areas that may require special attention or repairs.

Effective implementation of these techniques and strategies will not only ensure a clean and safe working environment but also contribute to enhanced productivity and employee satisfaction.

Consistency is key, so be sure to adhere to your cleaning schedule diligently to reap the full benefits of warehouse cleanliness.

FAQs on Cleaning a Warehouse

As you embark on your journey to maintain a clean and organized warehouse, you may encounter several questions and concerns.

Below, we address some of the most frequently asked questions (FAQs) regarding warehouse cleaning to provide clarity and guidance.

Common Questions About Warehouse Cleaning

- Warehouse cleaning involves a range of tasks, including sweeping, mopping, dusting, and sanitizing, aimed at maintaining cleanliness and orderliness in industrial facilities.

How Often Should a Warehouse Be Cleaned?

- The frequency of warehouse cleaning depends on various factors such as the size of the facility, the type of products stored, foot traffic, and industry regulations. In general, warehouses should be cleaned daily or weekly to prevent the buildup of dirt and debris.

What Are the Biggest Challenges in Cleaning a Warehouse?

- Some of the biggest challenges in warehouse cleaning include managing large floor areas, reaching high shelves and ceilings, dealing with heavy equipment and machinery, and ensuring compliance with safety regulations.

Are There Specialized Cleaning Services for Warehouses?

- Yes, there are specialized cleaning services that cater specifically to the needs of warehouses. These services often include deep cleaning, high-level dusting, equipment cleaning, and floor maintenance tailored to industrial environments.

What Safety Measures Should Be Taken During Warehouse Cleaning?

- Safety should be a top priority during warehouse cleaning. Some essential safety measures include providing proper training to cleaning staff, using personal protective equipment (PPE) such as gloves and masks, ensuring proper ventilation, and following safety guidelines outlined by regulatory agencies like OSHA.

How Can I Ensure Efficient Cleaning Without Disrupting Warehouse Operations?

- To ensure efficient cleaning without disrupting warehouse operations, consider scheduling cleaning tasks during off-peak hours or downtime. Divide cleaning responsibilities into manageable sections, prioritize high-traffic areas, and coordinate with warehouse staff to minimize disruptions to workflow.

By addressing these common questions and concerns, you’ll be better equipped to tackle the challenges of warehouse cleaning and maintain a safe and hygienic environment for your employees and inventory.

Occupational Safety and Health Administration (OSHA) – Warehouse Safety

Material Handling Institute (MHI) – Warehouse Cleaning Best Practices

National Fire Protection Association (NFPA) – Fire Safety in Warehouses